Select Language:

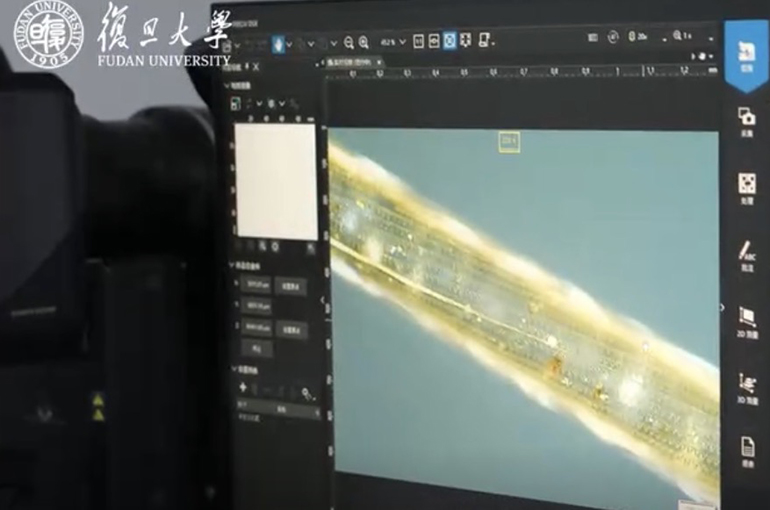

A team of Chinese researchers has achieved a groundbreaking milestone: the development of a “fiber chip,” integrating high-density circuits into a fiber thinner than a hair strand. This innovation signifies a significant departure from traditional silicon-based chips, according to publication in a prestigious scientific journal.

Led by scientists from Fudan University, the fiber chip contains approximately 100,000 transistors per centimeter and delivers processing power comparable to many standard commercial chips. Its design offers distinct advantages, such as exceptional flexibility, allowing it to stretch, bend, twist, and be woven into fabrics. This advancement could play a critical role in emerging industries like brain-computer interfaces, electronic textiles, and virtual reality.

The research team, operating within Fudan University’s State Key Laboratory of Molecular Engineering of Polymers and its Laboratory of Advanced Materials, has introduced the concept of “fiber devices” and has successfully developed over 30 different types to date.

Future wearable technology stands to benefit immensely from fiber-based solutions, as fibers serve as an ideal platform. Since these fiber chips do not need external processors, they can be woven directly into soft, breathable electronic textiles. The potential commercial applications are vast — clothing could function as smart displays, and in remote robotic surgeries, fiber chips embedded in tactile gloves could simulate the sensation of various objects with high precision, greatly enhancing human-machine interaction.

Flexible, fiber-based smart gloves could also improve the sensitivity of doctors during remote surgeries, according to a doctoral student involved in the project. Looking forward, once brain-computer interfaces are implanted, there may be no need for external equipment to gather or analyze data.

This development has sparked excitement among medical device developers. Industry insiders believe fiber chips could revolutionize implantable medical devices by drastically reducing size and enabling circuits and signal transmission to be integrated into a single fiber — an innovation that would be especially valuable for internal medical implants.

The team’s achievements have been recognized with multiple features in leading scientific journals, and some of their technologies have already been adopted by top domestic companies. These companies have established manufacturing lines for light-emitting fibers, fiber-based lithium-ion batteries, and other products, with early applications in automotive and apparel sectors.