Select Language:

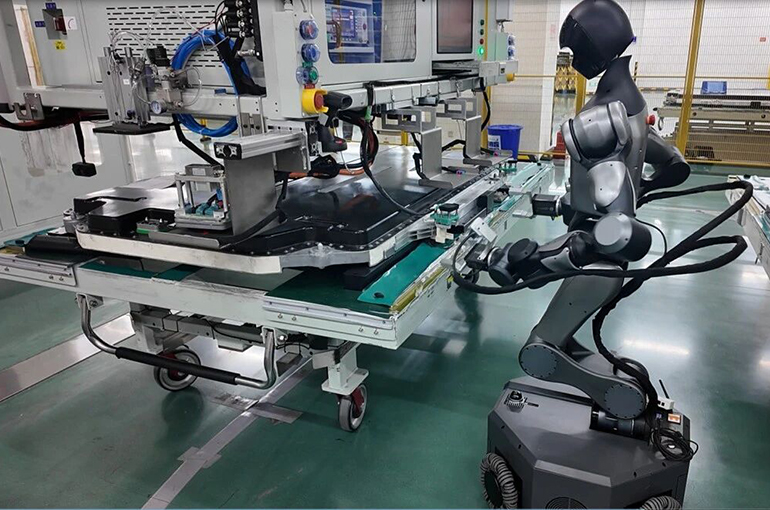

Contemporary Amperex Technologies, a global leader in electric vehicle batteries, has incorporated Xiao Mo embodied intelligent robots into its manufacturing process at the Luoyang facility in Henan province. These robots are tasked with handling intricate operations, including assembling battery connectors.

The factory has become the first in the world to integrate embodied intelligent robots within its battery pack assembly lines, announced the company late yesterday. Developed by Spirit AI, a startup based in Hangzhou with backing from the company’s founder, Xiao Mo robots perform critical final functional testing of battery packs before they leave the production line. This testing involves precisely connecting high-voltage test plugs to specific points on the battery packs.

The deployment of Xiao Mo robots is expected to significantly lower defect rates, improve product consistency, and boost productivity—tripling the daily output compared to traditional manual work. Traditionally, functional testing relied heavily on manual processes, which posed risks such as high-voltage arcing and inconsistent quality and efficiency.

Equipped with an advanced end-to-end vision-language-action system, Xiao Mo boasts exceptional environmental awareness and adaptability to various tasks. It effectively positions components with high accuracy, ensuring reliable performance, and can dynamically modify its operating parameters to accommodate different battery models.