Select Language:

The Internet of Things operating system created by China Southern Power Grid, known as Dianhong, is revolutionizing the fundamental operations within China’s power industry.

“Previously, installing and commissioning a single device took about four hours, but now, with remote control capabilities enabled by Dianhong, the process can be completed in just 30 minutes,” stated Du Shaohui, senior manager at the Dianhong Operations Center, during a recent on-site visit.

“Maintenance for power equipment used to require in-person visits, which was time-consuming for frontline workers and posed safety risks,” Du explained. “Having connected the equipment to Dianhong OS, the upgrade process has been shortened from three hours to just 20 minutes.”

Development of this system began in 2023, when the company linked tens of thousands of devices involved in power generation, transmission, distribution, and consumption through a unified platform, and began using peripheral tools like drones for remote management and inspection.

Dianhong was primarily built on two major open-source projects from Huawei Technologies: OpenHarmony and OpenEuler. Over the past two years, the company has worked with ecosystem partners to fully upgrade and transform the power supply system, covering the entire chain from transmission and transformation to distribution, consumption, and dispatching.

“The new power system faces real-world challenges, such as managing a vast array of terminals and data silos, as well as complex business cooperation,” said Xuan Liang, deputy general manager of the company’s digitalization department. “Using Dianhong has established a highly efficient link between business requirements and the technical backbone.”

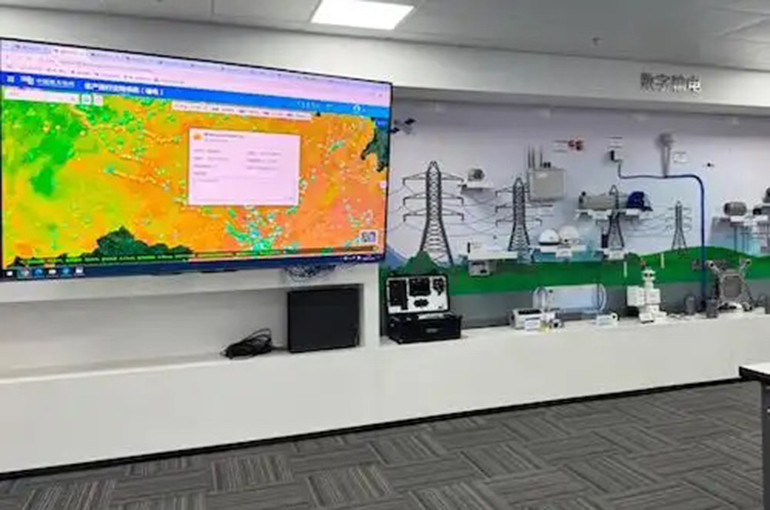

With continuous enhancements, Dianhong supports an expanding array of smart terminals, including smart meters, IoT switches, and micro sensors. Du added that Dianhong enables unified management and collaborative interaction among power equipment, imparting a kind of “soul” to devices like monitoring systems, cameras, and sensors.

The company has developed a comprehensive three-dimensional monitoring system that spans space, air, and ground. Beidou satellites can detect minute displacements in power towers, drones follow pre-set patrol routes to identify potential issues, and Dianhong terminals monitor for dangers such as wildfires and drifting objects in real-time.

The non-contact fault detection feature can accurately locate fault points within a 30-kilometer range, with an error margin of no more than 300 meters.

Nevertheless, Xuan emphasizes that digital transformation isn’t solely about technological innovation within the industry, but also about strengthening connections with partners across various sectors.

To foster a community around the power OS, major state-owned energy companies, research institutions, and ecological enterprises—including Inner Mongolia Power Group and power generation firms—have established an open-source ecosystem, Xuan explained.

This ecosystem acts as a resource hub for entities across the supply chain, encouraging widespread adoption of the open-source Dianhong platform in diverse industries, he noted.

Over 500 manufacturers have become part of the Dianhong network and are adapting the system for more than 3,000 different terminals, according to recent data.

By aggregating resources and applying scenarios throughout the supply chain, Dianhong is heading toward the aim of “entering thousands of industries and households,” stated Xuan. He predicted its future applications could expand to agriculture, transportation, mining, and other sectors.