Select Language:

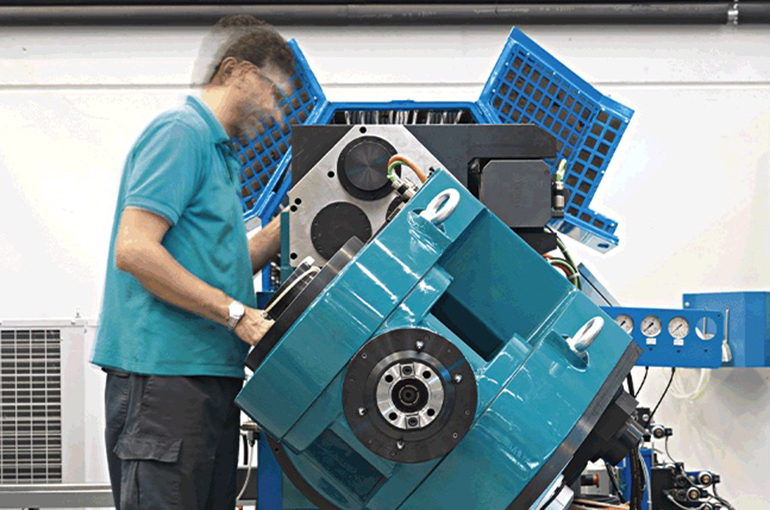

On November 5th, the latest model of the Speedmat horizontal boring and milling machine, created by a European machine tool manufacturer at its Lingang Special Area plant—located within Shanghai’s Free Trade Zone—drew considerable attention at the China International Import Expo’s technology equipment section.

“This is our fifth year participating in this event,” explained the chief financial officer of the Shanghai-based machine tool company. “We meet with many renowned manufacturers from around the world, and every year, it’s been incredibly beneficial.”

He added, “Participating allows us to connect with more customers and simultaneously demonstrate our localization capabilities. Among foreign machine tool brands operating in China, our level of local integration is the highest—about 85% of our suppliers are based here, which accounts for 85% of the value of our goods.”

Founded in 1926, the company introduced its first machine to the Chinese market in 1989. In 2011, it established a wholly owned subsidiary in Lingang to pursue a strategy of “manufacturing in China for China.” Over the decade, the company’s revenue has grown tenfold, according to the general manager.

Being situated in Shanghai offers strategic benefits, according to the company’s operations director, with close proximity to suppliers in Jiangsu and Zhejiang, enabling seamless communication and resource sharing—a crucial factor in maintaining high standards.

The Lingang manufacturing facility is equipped with state-of-the-art production tools and boasts a full-fledged R&D department staffed by highly skilled professionals capable of engaging directly with customers, conducting research, and managing production based on specific needs.

“Our R&D efforts are all centered at Lingang, which has the optimal conditions—such as a robust supply chain and available talent,” said the CFO.

The operations director also highlighted that “what truly sets us apart from competitors is the solutions we offer. With nearly a century of experience and accumulated expertise, we hold a leading position in the industry.”

Amid the market’s ongoing adjustments, the company remains optimistic about future opportunities. The manufacturing industry in China is shifting from rapid expansion to a focus on quality and innovation, which the company understands well.

“It’s a bit quieter than before,” the operations director noted about the current Chinese market, “but this shift reflects a change in focus—now the industry emphasizes automation, efficiency, and cost reduction.”

He sees this transition as a positive development, describing it as a “warm-up” preparing companies for the next stage of growth. This new approach, he says, aligns well with PAMA’s core strengths.

“Our ability to provide tailored solutions helps customers boost productivity, increase efficiency, and improve profitability,” the director explained. “When our clients succeed, we succeed as well.”

The company’s key clients include major names like Caterpillar, FMC Corporation, and Rolls-Royce. Last year, their revenue exceeded 150 million euros (about 172.4 million USD), with the Lingang plant performing particularly well.

“In recent years, our output has doubled,” the CFO stated, noting that the factory expanded nearly twofold last year by adding approximately 2,000 square meters of space.

Looking ahead, the company’s plans are cautious but adaptable. The operations director mentioned, “In the short term, we don’t have plans to build a new factory, but we’re aware that things can change rapidly in China, so we remain prepared to respond swiftly.”